Codo Flux

TIME

2023

ROLE

AI-POWERED ERP SYSTEM

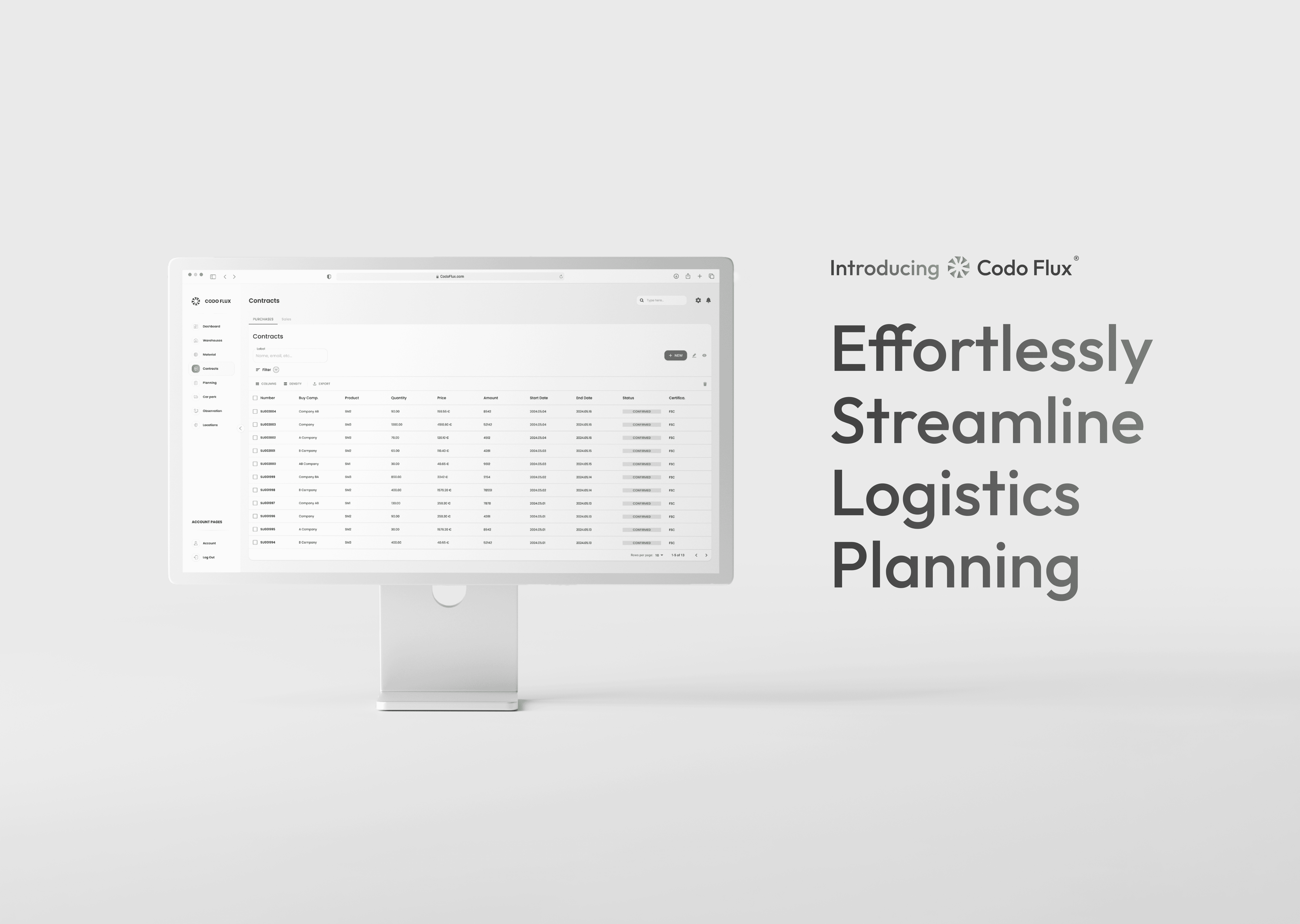

Transforming Biofuel Production with Codo Flux

Codo Flux is an innovative IT system designed to optimize the wood chipping and transportation process for biofuel production.

By integrating cutting-edge technology with real-time data, Codo Flux enhances the efficiency of wood procurement, chipping, transportation, and sales.

The system automates resource planning, improves supply chain management, and ensures timely delivery of biofuel, making it an essential tool for companies in the bioenergy sector.

A leading company in the biofuel industry faced significant challenges in managing the complex processes of wood chipping, transportation, and biofuel distribution.

The operations involved multiple forest locations, variable weather conditions, and the need for precise coordination of resources like wood chippers and trucks. Inefficiencies in these processes led to delays, increased costs, and missed delivery deadlines, affecting overall profitability.

The company needed an integrated system to manage and optimize its supply chain, from wood procurement to final delivery.

The key challenges included:

01

Resource Allocation

Ensuring optimal deployment of wood chippers and trucks across multiple locations.

02

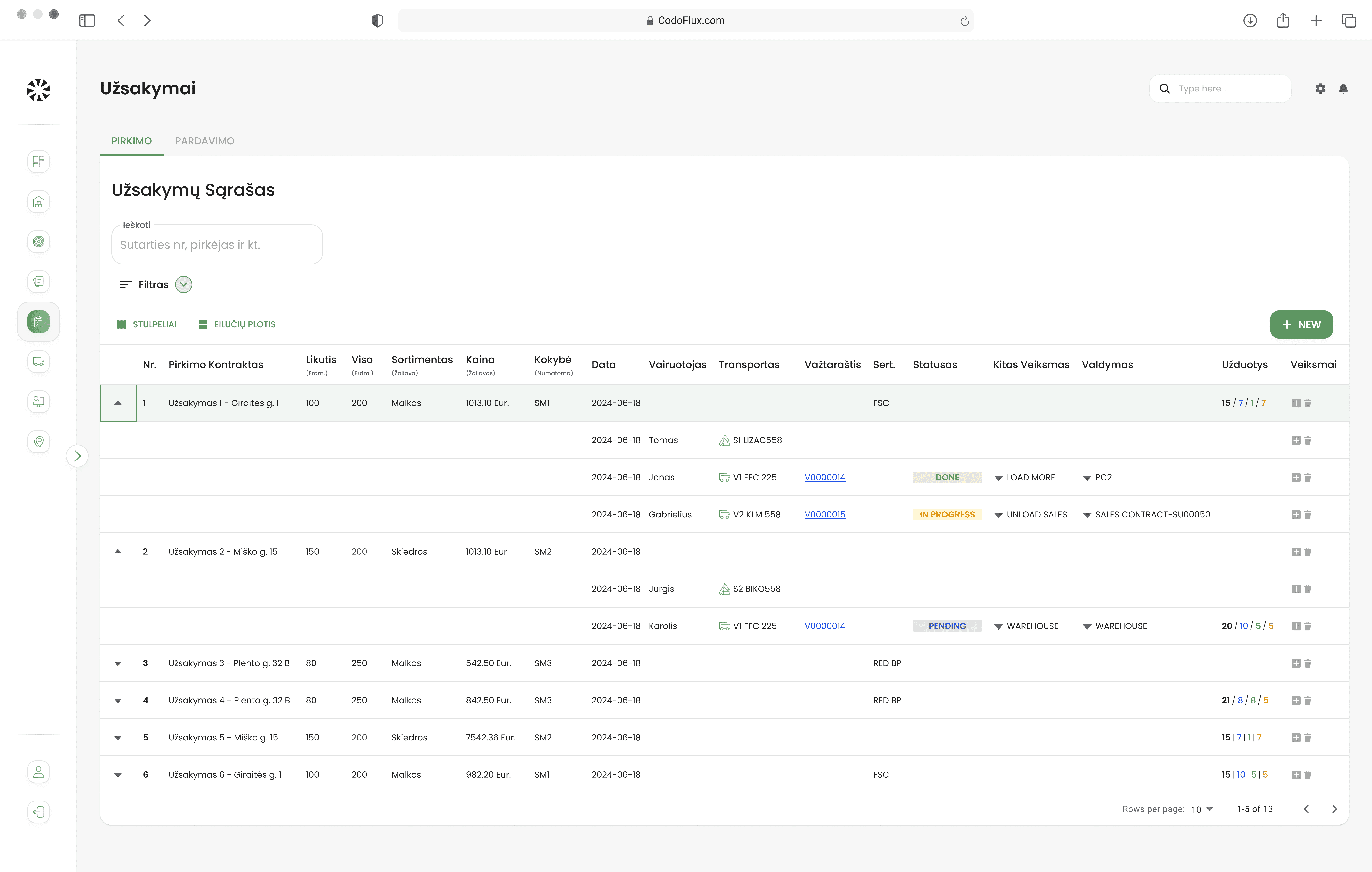

Real-time Monitoring

Tracking the status of chipping operations, transportation routes, and biofuel quality in real-time.

03

Supply Chain Optimization

Predicting resource needs and planning routes that minimize costs and time.

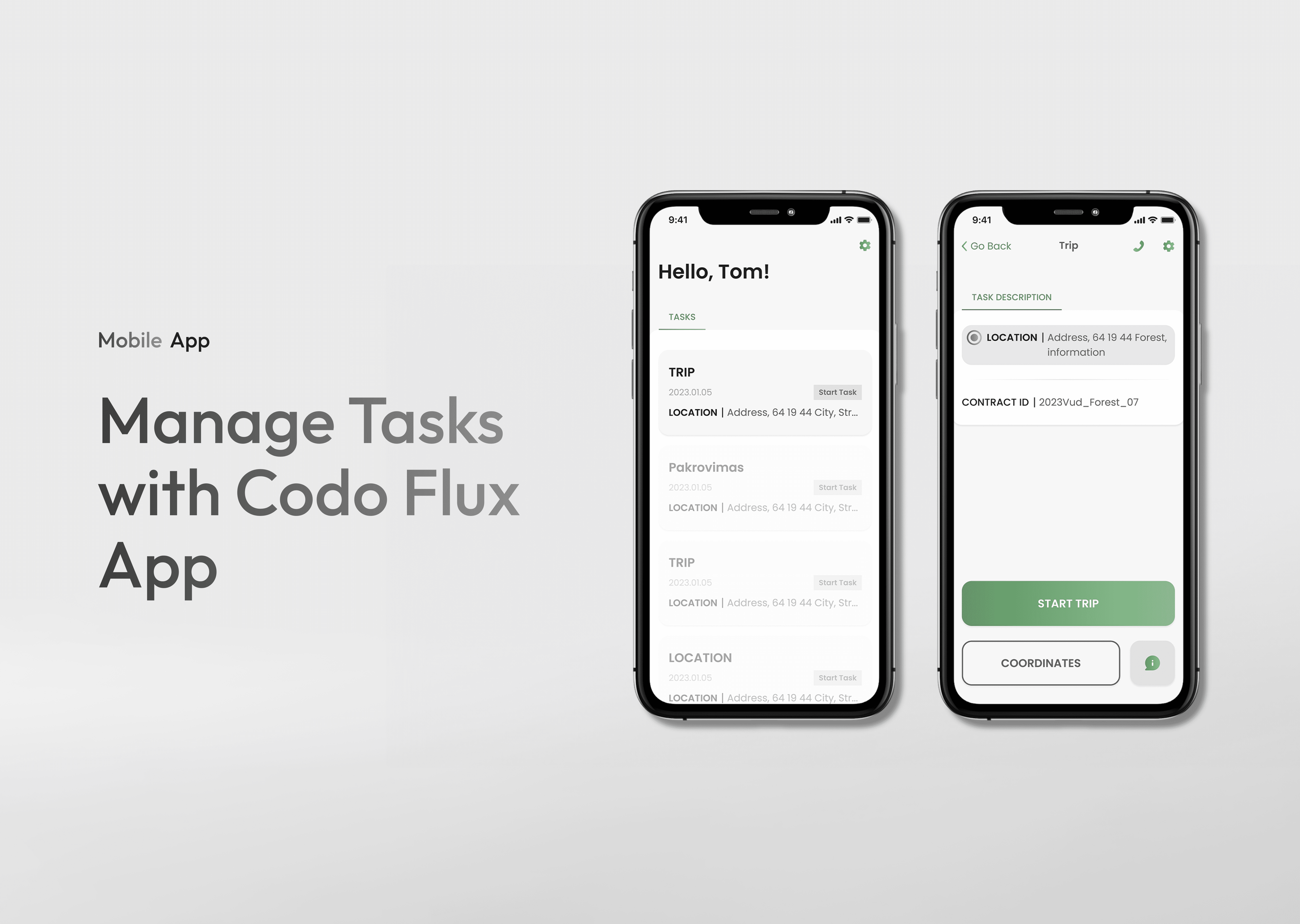

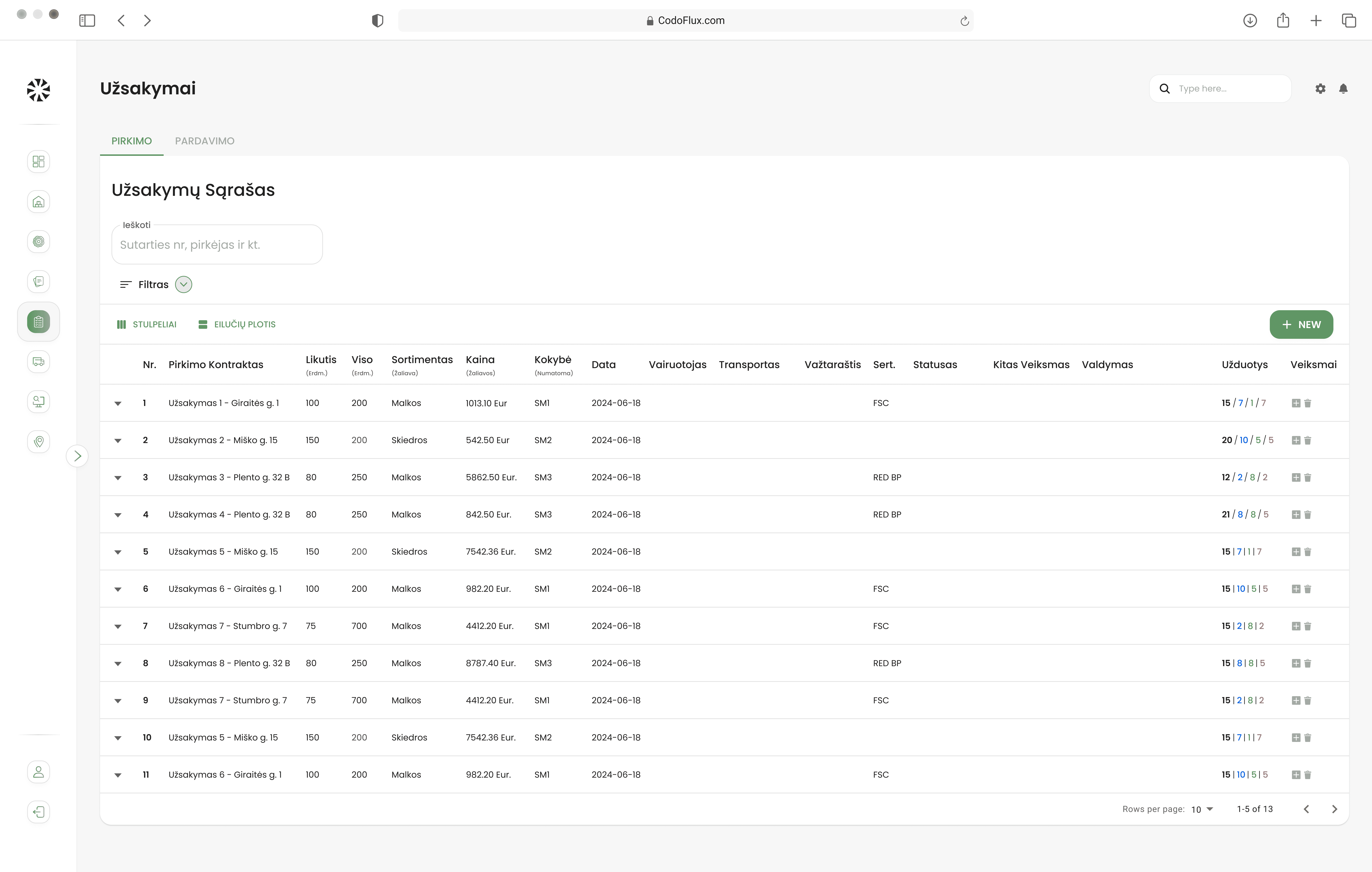

The company implemented Codo Flux, a comprehensive IT system developed to address these challenges.

Codo Flux integrates data from various sources, including telemetry sensors, weather conditions, and real-time GPS tracking, into a central database.

The system utilizes artificial intelligence to:

01

Optimize Resource Allocation

Automatically plan and deploy wood chippers and trucks based on real-time data.

02

Enhance Route Planning

Model optimal routes for transporting biofuel from forest locations to storage or power plants.

03

Predictive Analytics

Forecast wood supply needs and chipping efficiency to prevent bottlenecks and improve operational flow.

Since the implementation of Codo Flux, the company has seen a marked improvement in its operations

Increased Efficiency

Resource utilization has improved, reducing idle time for wood chippers and trucks.

Cost Savings

Optimized transportation routes have cut fuel costs by 15% and reduced delivery times by 25%.

Improved Biofuel Quality

Optimized transportation routes have cut fuel costs and reduced delivery times.

Codo Flux has transformed the company's biofuel production process, leading to enhanced efficiency, lower costs, and increased profitability.

By leveraging advanced technology and real-time data, the system has positioned the company as a leader in the bioenergy sector, capable of meeting the growing demands of sustainable energy production.

CONTACT

Transform your business with Codo Lab - Let’s begin today

Schedule a call

Press a button to easily schedule a call with our team.